May 24, 2025·8 min

Building a Subscription Box Web App for Orders & Logistics

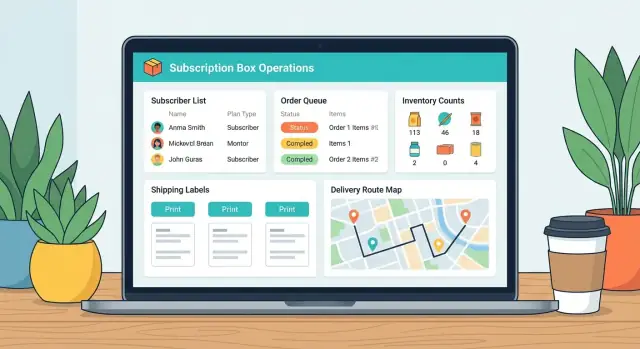

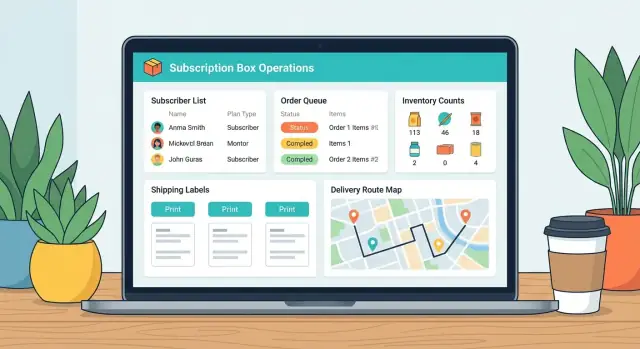

Learn how to plan, build, and launch a web app for subscription box brands to manage subscribers, orders, inventory, shipping, delivery tracking, and returns.

Learn how to plan, build, and launch a web app for subscription box brands to manage subscribers, orders, inventory, shipping, delivery tracking, and returns.

A subscription box “orders + logistics” app is the control center that turns recurring payments into real boxes that leave the warehouse on time—every cycle, with minimal surprises. It isn’t just an order list: it’s where subscription status, inventory reality, warehouse work, and shipping proof meet.

Subscription operations sit between three moving parts: recurring renewals, limited inventory, and time-boxed shipping windows. Your app should translate “this customer renews on the 1st” into “these items must be allocated, kitted, packed, labeled, and scanned by Tuesday.”

Teams usually struggle with:

An ops manager needs a high-level view: what’s shipping this week, what’s at risk, and why.

Warehouse staff need a simple, scan-friendly workflow: pick lists, kitting batches, packing steps, and instant feedback when something is off.

Support teams need fast answers: where is the box, what was inside, and what can be replaced—without pinging the warehouse.

Success is measurable: fewer manual steps, fewer exceptions per batch, and clearer tracking from renewal → order → shipment. A strong signal is when your team stops living in spreadsheets and starts trusting one system to tell the truth.

Before you design screens or tables, get precise about what you’re actually selling and how it moves from “someone subscribed” to “box delivered.” Subscription box businesses can look similar from the outside, but operationally they vary a lot—and those differences dictate your app’s rules.

Write down your real flow as a sequence of states your team recognizes: signup → renewal → pick/pack → ship → delivery → support. Then add who owns each step (automation, warehouse, support team) and what triggers the next step (time-based schedule, payment success, stock availability, manual approval).

A useful exercise is to note where work currently happens: spreadsheets, email, a 3PL portal, carrier sites, payment dashboards. Your app should reduce context switching—not just “store data.”

Different box types create different data and rules:

Document which choices customers can make (size, variants, add-ons) and when those choices lock.

Your workflows depend heavily on where fulfillment happens:

Most complexity lives in exceptions. Capture policies for skips, swaps, gift subscriptions, address changes (especially near cutoff), failed payments, replacement shipments, and partial inventory shortages. Turning these into explicit rules early prevents “secret workflows” that only exist in someone’s inbox.

A clean data model is the difference between an order management system that “mostly works” and subscription box software your team can trust during peak fulfillment weeks. The goal is simple: every box, charge, pick list, and tracking number should be explainable from the database.

A Subscriber is the person (or business) you serve. Keep their identity stable even if they pause, switch plans, or run multiple subscriptions.

A Subscription represents the commercial agreement: plan, cadence (weekly/monthly), status (active/paused/canceled), and the key operational dates: next_bill_at and next_ship_at. Store shipping address history separately so old orders remain auditable.

Practical tip: model cadence as rules (e.g., “every 4 weeks on Monday”) rather than a single interval, so exceptions (holiday shifts, “skip next box”) can be recorded without hacks.

Your catalog should support:

In practice, you’ll want a BoxDefinition (what’s supposed to be inside) and BoxItem lines with quantities and substitution rules. This is where inventory tracking and fulfillment accuracy usually break down if it’s oversimplified.

Separate “what was purchased” from “what got shipped.”

This matters when you split shipments (backorders), ship add-ons separately, or replace a damaged box without re-billing.

Inventory needs more than “quantity.” Track:

Reservations should be tied to shipment order lines, so you can explain why something is unavailable.

A Shipment should store carrier, service level, label identifiers, and tracking number, plus a stream of tracking events (accepted, in transit, out for delivery, delivered, exception). Normalize delivery status so customer support can filter quickly and trigger replacements when needed.

Subscription box operations get messy when billing dates, shipping cutoffs, and customer requests aren’t governed by clear rules. Treat “subscription logic” as a first-class system, not a handful of flags.

Model the lifecycle explicitly so everyone (and every automation) speaks the same language:

The key is to define what each state allows: can it renew, can it create an order, can it be edited without approval?

Renewals should be governed by two separate cutoffs:

Keep these configurable per cadence (monthly vs. weekly) and per product line if needed. If you offer proration (e.g., upgrading mid-cycle), keep it optional and transparent: show the calculation and store it with the renewal event.

Customers will ask to skip a cycle or swap items. Treat these as rule-driven exceptions:

When a charge fails, define: retry schedule, notifications, and the point at which you pause shipments (or hold the order). Don’t let unpaid subscriptions silently keep shipping.

Every change should be traceable: who changed what, when, and from where (admin vs. customer portal). Audit logs save hours when reconciling billing disputes or “I didn’t cancel” claims.

Your order workflow needs to handle two rhythms at once: predictable “box cycles” (monthly) and faster repeat shipments (weekly). Design one consistent pipeline, then tune batching and cutoffs per cycle.

Start with a small set of statuses that every team member understands and that map to real work:

Keep statuses “truthy”: don’t mark Shipped until a label exists and the carrier tracking number is saved.

Batching is where ops apps save hours. Support multiple batch keys so teams can choose what’s most efficient:

Monthly cycles typically batch by box type + ship window, while weekly cycles often batch by ship date + zone.

Offer two fulfillment modes:

You can support both by storing the same fulfillment events (who picked what, when, and from which location).

Edits happen: address changes, skipped boxes, upgrade requests. Define cutoffs per cycle and route late changes predictably:

Create a dedicated queue with reasons and next actions for:

Treat exceptions as first-class: they need ownership, timestamps, and an audit trail—not just notes.

Inventory is where subscription box operations either stay calm or turn chaotic. Treat stock as a live system that changes with every renewal, add-on, replacement, and shipment.

Decide exactly when items are “spoken for.” Many teams reserve inventory when an order is created (e.g., at renewal time) to prevent overselling, even if payment happens later. Others reserve only after payment succeeds to avoid locking stock for failed payments.

A practical approach is to support both as configuration:

Under the hood, track On hand, Reserved, and Available (Available = On hand − Reserved). That keeps reporting honest and prevents customer support from promising items that are already allocated.

Subscription boxes are rarely “1 SKU = 1 shipped item.” Your inventory system should support:

When a bundle is added to an order, reserve (and later deduct) the component quantities, not just the box label SKU. This avoids the classic error where the system says “we have 200 boxes,” but you’re missing one key insert.

Forecasting should be driven by upcoming renewals and expected item usage, not just last month’s shipments. Your app can project demand from:

Even a simple “next 4 weeks” view by SKU can prevent rush orders and split shipments.

Make receiving fast: purchase order intake, partial receipts, and lot/expiry tracking if you need it. Also include adjustments for damaged goods, mispicks, and cycle counts—each adjustment should be auditable (who, when, why).

Finally, configure low-stock alerts and reorder points per SKU, ideally based on lead time and forecasted consumption, not a one-size-fits-all threshold.

Shipping is where subscription box operations either feel smooth—or chaotic. The goal is to turn “an order is ready” into “a label is printed and tracking is live” with as few clicks (and as few mistakes) as possible.

Don’t treat addresses as plain text. Normalize and validate them at two points: when customers enter them, and again right before label purchase.

Validation should:

Decide what you need first, because it affects UX and integrations.

Many teams start with fixed services for the MVP and add rate shopping later once weights and zones are predictable.

Your label flow should generate:

If you support international shipping, build “data completeness” checks so customs-required fields can’t be skipped.

Create a background job that ingests tracking events from carriers (webhooks when possible, polling as a fallback). Map raw carrier statuses into simple states like Label Created → In Transit → Out for Delivery → Delivered → Exception.

Bake rules into shipping selection: weight thresholds, box sizes, hazardous items, and regional restrictions (e.g., air service limitations). Keeping these rules centralized prevents last-minute surprises at the packing station.

Returns and support are where ops apps either save hours a day or quietly create chaos. A good system doesn’t just “log a ticket”—it connects RMAs, shipment history, refunds, and customer messages so a support agent can decide fast and leave a clear audit trail.

Start with an RMA (Return Merchandise Authorization) that can be created by support or (optionally) by the customer from a portal. Keep it lightweight, but structured:

From there, drive the next step automatically. For example, “damaged in transit” can default to “replacement shipment,” while “changed mind” can default to “refund pending inspection.”

Replacements shouldn’t be manual re-orders. Treat them as a specific order type with clear rules:

Critically, the app should show original shipment tracking next to replacement tracking so agents stop guessing.

Support needs a guided decision: refund to original payment, store credit, or “no refund” with a reason. Tie that decision to the RMA outcome and capture support notes (internal) plus what was communicated to the customer (external). This keeps finance and ops aligned and reduces repeat tickets.

Templates save time, but they’re only useful when they pull in live data (box month, tracking link, ETA). Common templates:

Keep templates editable per brand voice, with merge fields and a preview.

Add simple reporting that ops will check weekly:

These metrics help spot whether issues come from warehouse throughput, carrier performance, or support staffing—without digging through spreadsheets.

A subscription box business lives or dies by operational rhythm: pick, pack, ship, repeat. The admin dashboard should make that rhythm obvious—what needs to happen today, what’s blocked, and what’s quietly turning into a problem.

Start by defining a few common roles and tailoring defaults, not capabilities. Everyone can use the same system, but each role should land on the most relevant view.

Keep permissions simple: roles control what actions are allowed (refunds, cancellations, overrides), while the dashboard controls what’s emphasized.

Make the homepage answer four questions instantly:

A small but powerful detail: every tile should be clickable into a filtered list, so teams can go from “there’s a problem” to “here are the exact 37 orders” in one click.

Admins don’t browse—they hunt. Offer a universal search box that accepts:

Then make list views filterable with saved presets (e.g., “Ready to ship – this week”, “Exceptions – address”, “Unpaid renewals”). On detail pages, prioritize “next action” buttons (reprint label, change ship date, reship, cancel/resume) above long histories.

Subscription operations are batch operations. Support the high-impact bulk tools:

Always show a preview: how many records will change, and what exactly will be updated.

Warehouse teams often use tablets or shared computers. Design for large touch targets, high contrast, and keyboard-friendly scanning workflows.

Use a mobile-friendly “shipping station” page with a minimal layout: scan order → confirm contents → print label → mark shipped. When the UI respects the physical workflow, errors drop and throughput rises.

A subscription box ops app lives or dies on consistency: renewals must run on time, orders can’t duplicate, and warehouse actions need a fast, predictable UI. The goal is less “fancy tech” and more “boring correctness.”

For most early teams, a modular monolith is the quickest path to reliability: one codebase, one deployment, one database, clear internal boundaries. It reduces integration errors while you’re still learning your workflows.

Choose API + frontend (e.g., backend service + separate React app) when you have multiple clients (admin web + warehouse mobile) or multiple teams shipping independently. The tradeoff is more moving parts: auth, versioning, and cross-service debugging.

If you want to prototype the admin UI and workflow quickly before committing to a full build, a vibe-coding platform like Koder.ai can be useful for generating a React-based admin app and a Go + PostgreSQL backend from plain-language requirements (with features like planning mode, source export, and rollback snapshots). It won’t replace operational design work, but it can drastically shorten the time from “workflow doc” to a working internal tool you can test in the warehouse.

Even in a monolith, treat these as distinct modules:

Clear boundaries make it easier to evolve without rewriting everything.

Ops data is relationship-heavy: subscribers → subscriptions → orders → shipments, plus inventory reservations and returns. A relational database (PostgreSQL/MySQL) fits naturally, supports transactions, and makes reporting straightforward.

Put time-based and external-work tasks in a job queue:

For payment and carrier webhooks, design endpoints to be idempotent: accept repeated events without double-charging or creating duplicate orders. Store an idempotency key (event ID / request ID), lock around “create order/charge,” and always log outcomes for audit and support.

Security and reliability aren’t “nice to have” for subscription box software—ops teams depend on accurate order data and customers trust you with personal information.

Start with least-privilege access. Most staff should only see what they need: for example, warehouse users can pick/pack without viewing full customer profiles, while support can issue replacements without editing billing settings.

Use secure sessions (short-lived tokens, rotation, CSRF protection where relevant) and require 2FA for admins. Add audit logs for sensitive actions: address edits, order cancellations, refund approvals, inventory adjustments, and role changes. Audit logs should record who did what, when, and from where (IP/device).

Use a payment provider (Stripe, Adyen, Braintree, etc.) for subscription billing and customer payment methods. Do not store card data yourself—store only provider tokens/IDs and the minimum billing metadata you need for operations.

Design for payment edge cases: failed renewals, retries, dunning emails, and “pause/skip” changes. Keep the “source of truth” clear—often the provider owns payment state while your app owns fulfillment state.

Define retention rules for PII (addresses, phone numbers) and logs. Provide export tools so operations can pull orders, shipments, and inventory snapshots for reconciliation and vendor handoffs.

Set up error tracking and alerting for job failures (renewal runs, label generation, inventory reservations). Monitor carrier API uptime and latency so you can quickly switch to manual label flows when needed.

Back up critical order and shipment data regularly, and run recovery tests—not just backups—to verify you can restore within your required timeframe.

An MVP for subscription box operations should prove one thing: you can run a complete shipping cycle end-to-end without heroics. Start with the smallest feature set that moves a subscriber from “active” to “box delivered,” and postpone anything that doesn’t directly affect that flow.

Focus on one box type, one cadence (monthly or weekly), and one warehouse workflow.

Include:

Prioritize tests that mirror mistakes and edge cases you’ll see in production.

Do a “minimum viable import” first:

Pilot with one box type or one region for 1–2 cycles. Keep a manual fallback (exportable order list + label reprint) until your team trusts the new workflow.

Track a few signals weekly:

If exception rate spikes, pause feature work and fix workflow clarity before scaling to more plans or regions.

It should connect the full chain from renewal → order → inventory allocation → pick/pack → label → tracking, so each cycle runs on schedule.

At minimum, it should prevent missed/duplicate renewals, overselling, label mistakes, and “what’s blocked vs ready?” confusion.

Separate them so you can keep customer identity stable while subscriptions change.

Use two cutoffs and make them configurable per cadence:

Route post-cutoff changes into either “next cycle” or a manual review queue.

Use explicit states and define what each state allows:

Track more than a single quantity:

Tie reservations to specific shipment order lines so you can explain shortages and prevent overselling.

Separate “what was purchased” from “what was shipped.”

This is essential for split shipments, add-ons shipped separately, and replacements without re-billing.

Model bundles as a sellable unit but reserve/deduct component SKUs during fulfillment.

Otherwise you’ll see false availability (e.g., “200 boxes available”) even when one insert or variant is missing.

Support both, but store the same underlying fulfillment events.

Either way, record who did what, when, and from which location.

Shipping should be “label-ready” by design:

Don’t mark an order Shipped until a label + tracking exists.

Build exception queues with ownership, timestamps, and next actions:

For support, tie RMAs/replacements/refunds to the original order + shipment so agents can answer “what shipped and where is it?” without asking the warehouse.

This avoids “mystery flags” and inconsistent automation.