Sep 21, 2025·8 min

JD.com’s Fulfillment Moat: Winning with Logistics Reliability

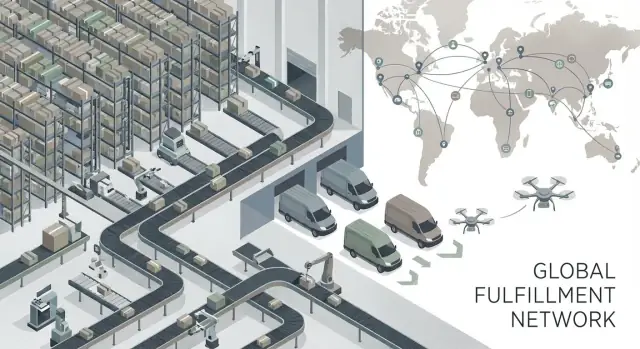

Learn how JD.com’s logistics-first model—warehouses, last-mile delivery, and clear SLAs—turns reliable fulfillment into a durable advantage.

What It Means to Compete on Fulfillment Reliability

Some e-commerce businesses can grow mainly through marketing, selection, and a slick website. Logistics-heavy e-commerce is different: the product experience is inseparable from the delivery experience. When customers buy everyday essentials, electronics, or time-sensitive gifts, the “real” product includes whether it arrives on time, intact, and with easy returns.

Reliability is the product

Fulfillment reliability means customers can predict what will happen after checkout: accurate stock availability, realistic delivery promises, consistent handoffs, low damage rates, and service recovery when something goes wrong. Speed helps, but speed without consistency trains customers to distrust promises—and that distrust is expensive.

What a logistics moat looks like

A competitive moat in retail logistics isn’t a single warehouse or a one-off “next-day” campaign. It’s a system that makes dependable delivery easier for you and harder for competitors to match. That system creates advantages that compound:

- Higher conversion because customers believe delivery dates

- More repeat purchases because delivery becomes “routine”

- Lower support costs as exceptions decrease

- Better unit economics as operations become predictable at scale

JD.com is a useful case study because it treats fulfillment as a core capability, not a back-office function. Its moat is built by making reliability an operational standard that competitors struggle to replicate quickly.

What this article will (and won’t) do

This is a strategy breakdown of how reliability can be engineered into an e-commerce business. It’s not a financial forecast, and it won’t assume every company should copy JD.com’s level of vertical integration.

The building blocks we’ll break down

Reliability is created through connected levers: a well-designed warehouse and hub network, smart inventory placement close to demand, strong last-mile control (or tight partner management), and tech plus data to keep performance consistent as volume grows.

Reliability as a Customer Promise (Not Just Fast Shipping)

Fast delivery is easy to market, but reliability is what customers actually experience day after day. JD.com’s advantage is less about the occasional “wow, it arrived in hours” moment and more about a consistent promise: your order will arrive when we said it would, with the right items, in good condition—and returning it won’t be a headache.

Define the promise in customer terms

For most shoppers, “reliable fulfillment” includes several basics working together:

- Predictable delivery windows (the ETA is believable, and updates are accurate)

- Order accuracy (right item, right variant, right quantity)

- Low damage and loss rates (good packing and careful handling)

- Simple returns (clear steps, fast pickup/refund, minimal friction)

Why predictability often beats peak speed

Many customers don’t need the fastest possible shipping; they need shipping they can plan around. A two-day delivery that arrives in two days is often better than “same-day” that slips to tomorrow night. Predictability matters for gifts, work-from-home essentials, and time-sensitive purchases—and it reduces the feeling of risk when clicking “Buy.”

How trust compounds into a moat

When shoppers learn that a retailer delivers reliably, behavior changes:

- More repeat purchases because the safest choice becomes the default choice

- Higher basket sizes because customers are less worried about partial deliveries, wrong items, or refund hassles

- Fewer cancellations because confident ETAs reduce second-guessing

Reliability also has a quiet operational payoff: fewer “where is my order?” contacts, fewer negative reviews driven by missed expectations, and less time spent manually resolving exceptions. Over time, those savings can be reinvested into even more consistent service—tightening the loop that makes JD.com hard to match.

Building the Physical Network: Warehouses and Regional Hubs

JD.com’s reliability advantage starts with an unglamorous choice: owning and tightly controlling key parts of the physical network. When warehouses are operated to a single standard—rather than stitched together from many third parties—service becomes more predictable. The same item is received, stored, picked, packed, and dispatched in the same way, regardless of city.

Why owned/controlled warehouses improve consistency

Control is less about real estate and more about execution. A warehouse you run can enforce one playbook: staffing levels by hour, slotting rules for fast movers, quality checks, and exception handling. That reduces the “randomness” customers feel—late dispatches, missing items, or inconsistent packaging—because fewer steps depend on external partners with different incentives.

Network density and cut-off windows

Reliability isn’t only about being close; it’s about having enough nodes to offer repeatable cut-off times.

With dense coverage—national hubs feeding regional hubs feeding local facilities—orders can be accepted later in the day while still meeting next-day or same-day promises. Shorter line-haul distances also mean fewer handoffs and less exposure to traffic, weather, and carrier capacity constraints. In practice, density converts speed into something customers can count on, not just occasional “record days.”

Standardization at every handoff

A controlled network can standardize the small actions that prevent big failures:

- Packaging rules that match product fragility and carrier handling

- Scanning at receiving, putaway, pick, pack, and dispatch to create traceability

- Training that makes exceptions (damaged goods, wrong SKU, address issues) handled the same way every time

These basics tighten the feedback loop: when something goes wrong, you can pinpoint where and fix the process—not just blame a partner.

Redundancy keeps uptime high during spikes

Peak demand and disruptions don’t just test capacity; they test routing options. Multiple regional hubs, backup line-haul routes, and the ability to rebalance inventory between nodes let the system keep promises when one facility is overloaded or a corridor is blocked. That redundancy is expensive—but it turns “best effort” delivery into a service customers can plan around.

Inventory Placement: Put the Right Items Near Customers

Fast delivery is often credited to trucks, riders, or “express” options. But the real lever is simpler: where the inventory is sitting before the customer ever clicks “buy.” If your best-selling items are already positioned close to demand, shipping becomes a short, predictable handoff—not a cross-country scramble.

Why placement beats pure speed

A carrier can only move a parcel so fast. Inventory placement removes distance from the equation. JD.com’s logistics advantage is rooted in consistently stocking the right products in the right regions, so the “default” path to the customer is short and repeatable.

Demand forecasting, explained plainly

Forecasting isn’t magic—it’s structured guessing based on patterns:

- History: what sold last week/month in each region

- Trends: whether demand is rising or falling

- Events: paydays, holidays, weather, local moments

- Signals: search views, carts, and wishlists that hint at future orders

The goal is not perfect prediction. It’s reducing surprises enough that operations stay stable.

Segment SKUs: fast movers vs. the long tail

Not every product deserves prime real estate.

- Fast movers (high volume): stock these in regional hubs or even closer nodes because every hour saved affects many orders.

- Long-tail items (low volume): keep these more centralized. You’ll ship farther occasionally, but you avoid tying up space and cash everywhere.

Safety stock, seasonality, and promotions

Reliability is mostly about preventing stockouts. That requires:

- Safety stock: a small “buffer” for demand spikes or supplier delays

- Seasonality planning: pre-build inventory before predictable peaks (school terms, holidays)

- Promotion planning: treat campaigns as a different demand curve; allocate inventory to regions where the promo will actually convert

Placed well, inventory turns delivery speed into a dependable promise, not a lucky outcome.

Last-Mile Control: The Most Visible Part of the Brand

For customers, “reliability” is judged at the doorstep. A perfect warehouse operation doesn’t matter if the courier shows up late, leaves without ringing, or marks an order delivered when it isn’t. This is why controlling last-mile operations can materially improve on-time performance: you can set standards, train to them, measure adherence, and fix issues quickly—rather than hoping a third-party network prioritizes your packages.

Why control raises on-time performance

When a retailer manages its own delivery workforce (or tightly managed partners), it can coordinate dispatch with warehouse cutoffs, local traffic patterns, and promised time windows. That alignment reduces the common failure points: missed handoffs, unclear ownership, and “it’s not our problem” exceptions.

Route planning, time slots, and re-delivery

Last-mile reliability is mostly planning discipline.

- Route planning: dynamic routing that reflects real driving time (not just distance) keeps stops realistic and reduces late cascades.

- Delivery time slots: clear windows set expectations and reduce “not at home” failures. Narrower slots cost more, but they cut rework.

- Re-delivery handling: a defined playbook—same-day retry rules, pickup options, and customer notifications—turns exceptions into predictable outcomes instead of churn.

Proof of delivery and accountability

Control also improves the “truth” of what happened. Proof of delivery isn’t just a photo; it’s scanning discipline at every step (pickup, sort, out-for-delivery, delivered) with timestamps and geo-data. When scans are consistent, you can pinpoint where delays start, reduce false delivery claims, and coach specific depots or drivers.

The trade-off

Owning last-mile is expensive: labor, fleet, training, and customer support. But service failures are expensive too—refunds, re-shipments, lost lifetime value, and reputational damage. The strategic bet is that paying for consistency yields a compounding advantage: fewer exceptions, lower cost per successful delivery, and a brand customers trust to keep promises.

SLAs and Operating Standards That Make Service Predictable

Keep control with source export

Move fast now, then export full source code when you need deeper customization.

Service level agreements (SLAs) are the “contract” behind reliability—even when customers never see the document. They translate a brand promise (“arrives tomorrow, intact”) into measurable commitments that shape staffing, cut-off times, carrier handoffs, and escalation rules.

How SLAs drive internal priorities

A useful SLA does two jobs at once: it sets the customer expectation and forces trade-offs inside the operation. If the SLA says 95% of eligible orders ship same-day, then labor planning, wave releases, packing stations, and linehaul departures must all align to that clock. Teams stop optimizing for local efficiency (“my station is fast”) and start optimizing for end-to-end outcomes (“the order leaves the building on time”).

Key reliability terms (and why they matter)

Common SLA metrics include:

- On-time rate: the share of orders delivered within the promised window.

- Fill rate: the share of order lines fulfilled completely (no missing items or substitutions).

- Pick accuracy: the share of picks that match the order exactly.

- Damage rate: the share of orders arriving damaged (often tracked per 1,000 shipments).

Each metric points to a different failure point: inventory availability (fill rate), warehouse process quality (pick accuracy), packaging and handling (damage rate), and network execution (on-time rate).

Exception handling: what happens when something goes wrong

Reliability isn’t “no problems”—it’s predictable recovery. Strong standards define what to do when an order is late, inventory is short, or a parcel is damaged: who gets alerted, how quickly the issue is diagnosed, what compensation is authorized, and how the customer is updated. Clear playbooks prevent improvisation and reduce the time an exception sits unresolved.

Why clear promises reduce churn

Overpromising creates disappointment even when performance is decent. A precise delivery promise and consistent service window reduce churn because customers can plan—especially for gifts, essentials, or time-sensitive purchases. In practice, a slightly slower but dependable SLA often beats inconsistent speed.

Tech and Data: How Reliability Scales Beyond Manual Processes

Reliability breaks down quickly when it depends on a few experienced people “remembering” what to do. JD.com’s advantage is treating fulfillment as an instrumented system: every step generates data, and that data feeds back into planning and customer communication.

Warehouse systems that prevent small errors from becoming big misses

At the center is a warehouse management system (WMS) that assigns locations, routes tasks, and verifies each touch.

Barcode/scan workflows matter more than they sound: when inbound cartons are scanned, items are tied to a specific bin; when pickers pull units, scans confirm the right SKU and quantity; when orders are packed, final scans validate the shipment contents. This reduces mis-picks, enables faster exception handling, and makes “predictable” a repeatable outcome rather than a goal.

Data that improves forecasting, replenishment, and labor planning

Reliability depends on having the right stock and the right people ready before demand arrives.

Demand signals (past orders, seasonality, promotions, local events) improve forecasting and replenishment timing, so popular items are less likely to hit stockouts. The same data supports labor planning: staffing and shift allocations can be adjusted to expected order volume, reducing backlogs that cause late dispatch.

Automation as consistency, not spectacle

Automation helps most when it removes variability. High-level examples include automated sorting to reduce routing mistakes, conveyor and scan tunnels to speed verification, and picking aids (like light-guided picking) to cut error rates—without assuming a fully “lights-out” warehouse.

Real-time tracking that lowers support load

When scans and handoffs update in real time, customers see accurate status and ETAs. That transparency reduces “where is my order?” contacts, and when issues occur (missed scan, delay at a hub), the system can trigger alerts and proactive updates—protecting trust even when delivery isn’t perfect.

Building reliability tooling faster (without a long dev cycle)

One practical takeaway for operators is that many reliability wins come from lightweight internal tools—exception reason-code capture, carrier performance dashboards, cut-off monitoring, or a simple “backlog aging” view. Platforms like Koder.ai can help teams prototype and ship these kinds of web apps quickly via a chat-driven build workflow, then iterate as ops learns what metrics actually predict misses. That can be especially useful when you need a working dashboard now, not after a multi-quarter WMS re-platform.

The Cost–Service Trade-Off: Paying for Consistency

Plan before you build

Define KPIs and flows in planning mode, then generate the app from that plan.

Reliability isn’t free. The question is whether you want to pay for it directly (by owning more of the logistics stack) or pay for it indirectly (through refunds, lost repeat purchases, and weaker brand trust when deliveries slip).

Unit economics, explained simply

Think in two dials:

- Cost per order: what it costs to pick, pack, and deliver one shipment.

- Service level: how consistently you hit the promise (right item, on time, undamaged).

Turning up service level often means extra spending—more warehouses, more drivers, better packaging, more buffer inventory. But service failures are also expensive: re-ships, customer support time, compensation, and the long-term cost of churn. JD.com’s bet is that predictable delivery reduces “hidden” costs and increases repeat buying, which can offset the higher operating spend.

Own logistics vs. partners: when each makes sense

Owning logistics (warehouses + last-mile) is most justified when:

- Order volume is high and dense in key regions.

- Delivery reliability is central to the brand promise.

- You sell categories where trust matters (electronics, appliances, high-value items).

Partners can be smarter when:

- Volumes are still uncertain.

- You’re expanding into low-density areas.

- Speed and reliability are “nice to have,” not the main reason customers choose you.

Many businesses start hybrid: keep critical lanes in-house and outsource long-tail geographies.

Utilization is the hidden cost lever

A warehouse or delivery fleet is cheaper per order when it’s busy. High utilization spreads fixed costs (rent, systems, staff training) across more shipments.

Peaks are the challenge. To avoid overbuilding, operators use tactics like temporary labor, overflow partners, pre-positioning inventory ahead of major promos, and setting realistic cutoffs so the promise stays consistent.

Customers notice reliability, not your cost structure

Most shoppers don’t care why shipping costs what it costs; they care whether the delivery promise holds. That’s why pricing works best when it reflects outcomes—clear tiers, honest ETAs, and fewer surprise delays—rather than trying to explain the logistics math.

Ecosystem Effects: Why Logistics Can Pull in More Merchants

A reliable fulfillment system doesn’t just keep customers happy—it changes who wants to sell on your platform.

When brands and third-party sellers see consistently on-time delivery, low damage rates, and predictable returns handling, they’re more willing to list their best products and launch new SKUs. Reliability lowers the “hidden costs” of e-commerce (angry customers, refunds, customer support burden), so merchants can focus on marketing and assortment instead of firefighting.

Reliability as a magnet for brands and sellers

For established brands, logistics performance is a proxy for brand safety. If delivery is messy, the customer blames the logo on the box—not the carrier. A platform known for dependable fulfillment can win exclusive launches, higher-margin categories, and larger catalog commitments because it protects brand reputation.

For smaller sellers, strong logistics can be a shortcut to credibility: they can compete with bigger players by plugging into a system customers already trust.

Seller standards: inbound rules that protect the promise

To keep the network predictable at scale, marketplaces typically enforce inbound and fulfillment requirements—things like labeling, carton dimensions, barcode accuracy, packaging standards, and appointment-based receiving. These rules feel strict, but they reduce warehouse exceptions that cause late shipments and mis-picks.

Platforms also set clear cutoffs (when orders must be confirmed and handed over) and require accurate inventory feeds so customers don’t buy items that aren’t actually available.

Quality control: penalties, audits, and performance tiers

Reliability becomes self-reinforcing when it’s tied to seller outcomes. Common mechanisms include:

- Audits (spot checks on packaging, authenticity, and order accuracy)

- Penalties for late dispatch, canceled orders, and high return rates

- Performance tiers that unlock benefits (better search placement, access to peak-season capacity, lower fees, or eligibility for premium programs)

The goal isn’t punishment—it’s making service quality measurable and economically meaningful.

Enabling premium services that raise the bar

Once the basics are dependable, the platform can sell “reliability upgrades” customers value: scheduled delivery windows, evening/weekend delivery, installation, haul-away, or white-glove handling for large appliances. Those services attract more merchants in bulky or high-consideration categories, expanding the marketplace mix while keeping the customer promise intact.

Metrics That Prove You’re Reliable (and Show Where You Aren’t)

Reliability only becomes a moat when you can measure it consistently, spot slippage early, and fix the underlying causes—not just apologize faster. The goal is a small set of metrics everyone trusts, reviewed on a tight cadence.

A simple KPI set (start here)

Keep the “scoreboard” short and tied to customer outcomes:

- On-time delivery % (by region, carrier, and promise tier)

- Order accuracy % (perfect orders: right item, quantity, packaging)

- Return cycle time (days from customer drop-off to refund/resellable)

- NPS or CSAT (post-delivery, segmented by delivery experience)

If you can only track two at first, choose on-time % and order accuracy %—they capture most reliability failures customers actually feel.

Leading vs. lagging indicators

Lagging indicators (like NPS, refunds, late deliveries) tell you you’ve already failed. Pair them with leading indicators that warn you earlier:

- Scan compliance (were required scans completed at pick/pack/dispatch?)

- Backlog (unshipped orders and aging by cutoff time)

- Missort rate (wrong hub/route assignments)

- First-attempt delivery success % (address quality, route planning, customer comms)

A practical rule: if a metric can be “fixed” by working overtime tonight, it’s usually lagging. If it points to a broken step (training, layout, system rule), it’s leading.

Weekly ops reviews and root-cause discipline

Run a weekly reliability review with one page per node (warehouse/hub/last mile). Start with exceptions: biggest on-time drops, top SKUs driving misses, and worst routes.

Use simple root-cause tags (inventory not available, capacity shortfall, missort, address issue, damage) and require one owner + one next action per major driver. Track whether actions reduced the problem the next week.

A lightweight dashboard for non-technical teams

Structure it as:

- Customer outcomes (on-time, accuracy, NPS/CSAT)

- Process health (scan compliance, backlog, missort)

- Capacity view (orders vs. staffing/vehicle plan)

The dashboard should answer two questions in under five minutes: Where are we failing the promise? and Which process step is causing it?

If you don’t yet have analytics engineering capacity, consider building a “minimum viable reliability dashboard” first (even if it’s imperfect) and iterating weekly. Tools like Koder.ai can be a pragmatic way to spin up an internal web dashboard quickly—then evolve it as your SLA definitions and exception taxonomy mature.

Risks and Failure Modes: What Can Break the Moat

Score last-mile reliability

Create a courier and route scorecard to spot missed windows and retries quickly.

Reliability is a moat only while customers experience it as “predictable.” The moment deliveries become uncertain, the advantage can turn into a cost center—because you’re still paying for the network, but no longer earning trust.

Where reliability commonly breaks

The biggest failure points are rarely mysterious; they’re the same stressors that hit every logistics operator:

- Weather and local disruptions (storms, floods, road closures) that cascade into missed routes.

- Labor shortages in warehouses or last-mile teams, especially during holidays and major promotion events.

- Supplier delays and inbound variability that cause stockouts even when demand forecasts were right.

- Demand spikes (campaigns, viral products) that overload pick/pack capacity and line-haul schedules.

Resilience tactics that actually help

Moats don’t come from avoiding problems—they come from absorbing them without breaking the customer promise.

A few tactics are consistently effective:

- Buffer stock on high-velocity SKUs, placed regionally to protect ETAs when inbound slips.

- Alternate carriers and routing options so a single bottleneck doesn’t freeze a whole region.

- Flexible labor models (cross-trained staff, surge staffing, extended shift playbooks) to handle peak weeks without chaos.

The important detail is orchestration: these options must be pre-negotiated, rehearsed, and triggered by clear thresholds, not improvised mid-crisis.

The hidden risk: overbuilding the network

A large network can become a liability if utilization drops. Overcapacity shows up as fixed costs, underused automation, and pressure to “fill the machine” with low-margin volume.

Stage investments: expand hub-by-hub, automate where volumes are stable, and use temporary capacity (pop-up sortation, short-term leases) during uncertain growth periods.

When ETAs slip, communication is part of the service

Customers can tolerate delays better than uncertainty. The baseline plan should include proactive notifications, updated ETAs, clear cut-off times, and easy cancellation/refund paths. If you publish service promises, keep them simple—and tie escalation rules to them—so frontline teams can act consistently.

Practical Takeaways: How to Apply the JD.com Playbook

JD.com’s advantage isn’t only “shipping fast.” It’s making delivery outcomes predictable—so customers trust the promise, and the business can scale without constant firefighting. You can borrow the logic even without owning a massive fleet.

The repeatable principles

1) Network logic (where you can reach reliably): Define the service area you can consistently hit, then expand only when performance stays stable.

2) Inventory placement (what you keep close): Put your most common, most time-sensitive SKUs nearest to demand. Reliability improves more from “right item, right place” than from heroic last-minute shipping.

3) Standards (how work gets done every time): Clear cutoffs, packing rules, carrier handoff steps, exception handling, and customer messaging reduce surprises.

4) Feedback loops (how you get better weekly): Track failures, tag root causes, and fix the upstream step—don’t just refund and move on.

A starter plan for smaller retailers (step-by-step)

-

Pick one promise you can keep. Example: “Ships same-day for orders placed by 2pm; delivered in 2–4 days.” Publish it and align operations to it.

-

Split SKUs by velocity and pain. Identify the top 20% SKUs that drive 80% of orders, plus any items that often cause delays (fragile, bulky, hazmat, supplier lead-time issues).

-

Create a “reliability bundle.” For those SKUs: higher safety stock, pre-labeled packaging, dedicated pick locations, and a primary + backup carrier option.

-

Standardize handoffs. One packing checklist, one label workflow, one end-of-day dispatch routine. Small consistency beats occasional speed.

-

Instrument exceptions. Every late shipment gets a reason code (stockout, pick error, carrier miss, address issue). Review weekly and fix the biggest driver.

If you want to move faster on the instrumentation step, you don’t necessarily need a full rebuild of your stack. Many teams start by shipping a small internal app for exception capture and weekly reporting, then expand. A vibe-coding platform like Koder.ai can help you produce that “first working version” quickly (and iterate without heavy handoffs), while still keeping the output practical for ops teams.

Next 90 days: “do next” checklist

- Week 1–2: Define delivery promise + order cutoff; audit top delay causes.

- Week 3–4: Re-slot fast movers; set reorder points; create packing SOP.

- Month 2: Add carrier backup; implement exception reason codes; tune customer notifications.

- Month 3: Set SLAs internally (pick time, pack accuracy, dispatch rate); run a weekly reliability review.

For cost and plan comparisons, link your ops work to clear pricing assumptions (/pricing). For more process templates and ops playbooks, keep a running internal reading list (/blog).